Technical requirement for PCB Assembly:

v Professional Surface-mounting and Through-hole soldering Technology

v Various sizes like1206,0805,0603,0402,0201 components SMT Tech

v ICT(In Circuit Test),FCT(Functional Circuit Test) technology

v PCB Assembly With UL,CE,FCC,Rohs Approval

v Nitrogen gas reflow soldering technology for SMT

v High Standard SMT&Solder Assembly Line

v High density interconnected board placement technology capacity

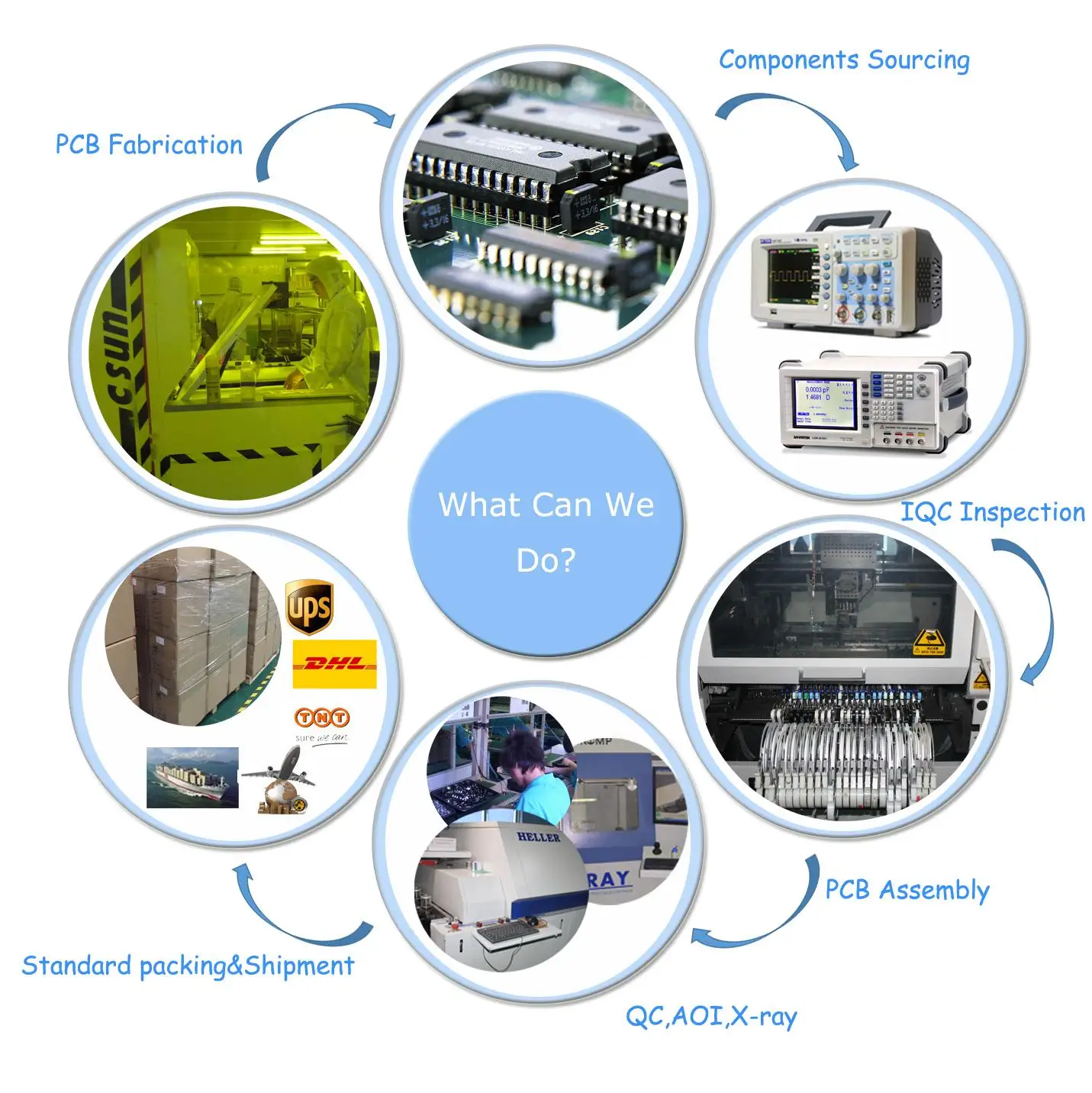

Eastwin PCB&PCBA Contract Manufacturing Services Including Blows:

v Electronic Components Sourcing Services

v PCBA Assembly Services:SMT,DIP,BGA...

v Function Test

v Stencil,Cable and Enclosure Assembly

v Reverse engineering service

v Standard Packing and On time Delivery

Main Products Application

v Household Appliances

v Medical Products

v Automotive Products

v Industrial Products

v Communication Products(AVL/GPS/GSM Devices)

v Consumer Electronics

Production Details:

1) Material Management

Supplier → Components Purchase → IQC → Protection Control → Material Supply → Firmware

2) Program Management

PCB Files → DCC → Program Organizing → Optimization → Checking

3) SMT Management

PCB Loader → Screen Printer → Checking → SMD Placement → Checking → Air Reflow → Vision Inspection → AOI → Keeping

4) PCBA Management

THT→Soldering Wave (Manual Welding) → Vision Inspection → ICT → Flash → FCT → Checking → Package → Shipment

Welcome To Eastwin:

1.Related Certificate --- UL ,ISO9001:2000 , TS16949, Rosh.

2.100% electrical test, AOI testing, four times 100% QC inspection beofre shipping.

3.High reliable, Germany equipment ,competitive price and Speedy delivery.

4.Fast Prototype Service.

5.One stop electronic assembly service(provide prototype, plastic injection molding, part painting,

components purchasing, SMT COB,DIP,PCBA service as one unit).

Our customers reviews